Technology

Technology

It is with great satisfaction that the ongoing development of our machine facility gives us a competitive edge in the marketplace. Keeping processes in-house means that we are able to ensure the utmost quality and high standard of service at every stage of individual projects. To ensure everything is carried out in accordance with the design and technological requirements, our company structure includes a fully-staffed Quality Department who continually monitor product compliance. Your orders are meticulously handled by a team of trained specialists - from the earliest stages of the design phase, through production and onto safe and secure packaging.

Customer Service

We operate on the ERP system Microsoft Dynamics NAV. This tool ensures security and excellent data archiving. With our colour management expertise, we provide specialized colour matching services. We work on a project basis, providing non-binding quotes and operate under confidentiality agreements (NDA).

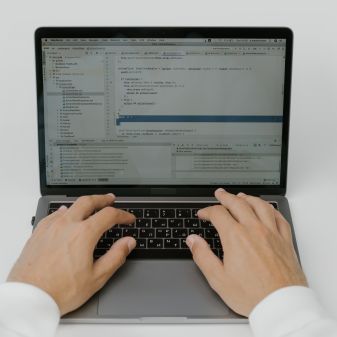

ERP system

Microsoft NAV ERP system

A modern system for management, analytics and organisation of tasks. It provides our employees with an efficent tool with which to work. Our clients can be sure that their project data is securly archived.

QQT

Quick Quotation Tool (QQT)

Proprietary system for individual valuations. Access to QQT is possible at any time, from anywhere in the world. A moment is all it takes to perform a price validation. Soon QQT will be available to selected clients.

Consulting

Experience and knowledge are our competitive advantage. That is why we are able to offer our clients the best solutions.

Colour management

We have specialized skills in colour management for digital printing technologies.

Colour matching

We select colours to match the sample provided by the Client on various substrates.

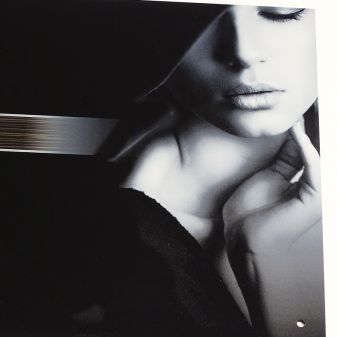

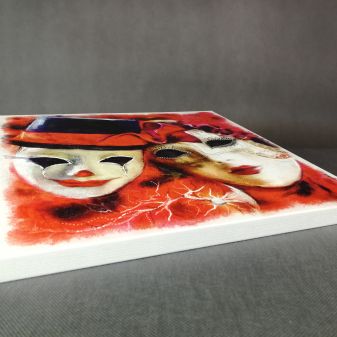

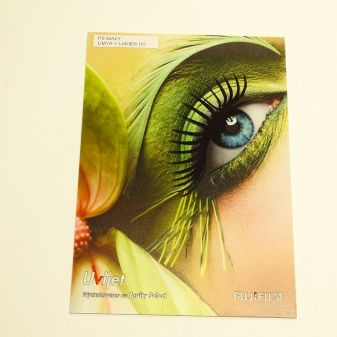

Printing

Printing is the most time-proven area of our activity. We specialise in this category of services, lending our professional capabilities to the most demanding areas of industry. We are able to print on a numerous variety of substrates, for example: plastics of the types PVC, HIPS, ABS, PMMA, PC PET, PP, PE among many others and also on wood and wood-based materials, namely fibreboard, melamine, MDF, HDF, plywood, dibond and similar, cardboard-foam, corrugated board and on metals, such as aluminum, steel, textiles and leather.

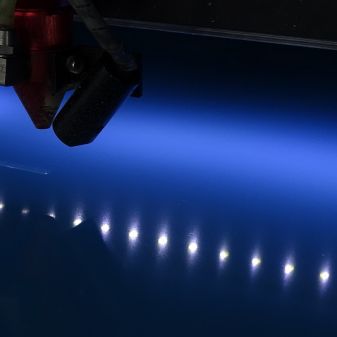

UV digital printing

- Sericol Acuity F, working area 2500 x 3050 mm (CMYK + white

-

Sericol Acuity Select, working area 2500 x 1250 mm (CMYK + white + varnish)

-

Sericol Acuity: working area 2500 x1250 mm (CMYK + white)

UV Digital Printing is the most popular service in our portfolio. Color management and making color profiles on our own determines the unique quality of printing. Be sure to ask about the possibility of hybrid printing!

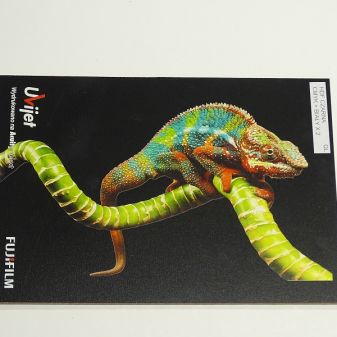

Solvent roll printing

-

Mimaki JV300 -160,

-

Mimaki JV5 -160,

-

Mimaki JV5-130,

We achieve photographic quality through this technology. Three printing devices offer great price flexibility and attractive lead times.

Barcodes and labels

Labels and barcodes made using various technologies for the many types of industry are very popular among our clients.

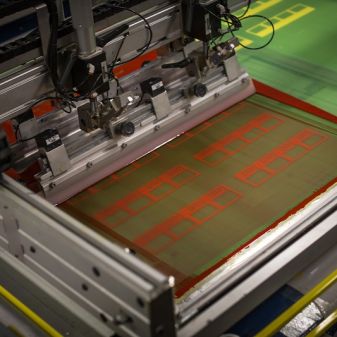

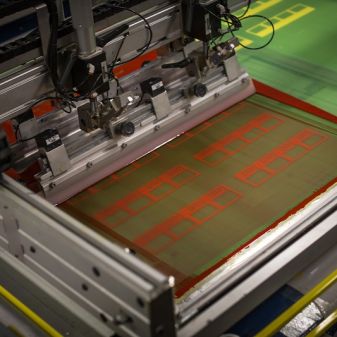

Graphic screen printing

-

Renegade 4056 UV, with a working area of 1400x1000 mm

-

Thieme 1040, with a working area of 1400 x 1000 mm

-

Oltronik, taking elements of up to 250 mm in thickness

Graphic screen printing is the most seasoned technology in our portfolio. We possess several technological lines and extensive experience in screen printing on various substrates (including self-adhesive films, PVC, cardboard, HIPS, PMMA, and others according to the customer's needs). Be sure to ask about the possibility of hybrid printing.

Industrial screen printing

-

Oltronik, elements up to 250 mm thickness

-

Renegade 4056 UV, working area 1400x1000 mm

-

Thieme 1040 1400 x 1000 mm

We undertake difficult and knowledge-intensive implementations. We print on polyester, polycarbonate, PMMA films, solid polycarbonate, PP, PE, HIPS, powder coated steel, spatial elements from injection and glass.

Screen printing on textiles

We make multi-colored screen printing on textiles. This is a very popular solution for large quantity prints.

Pad printing

Printing technology on flat, convex and concave substrates. Among others on PP, PE, Hips, PS, powder coated steel, elements from injection moulding.

Digital printing in small format

We perform small printing with an economical, fast and reliable Konica Minolta device.

Hybrid printing

We combine two techniques on one substrate: screen printing and digital UV printing. We achieve realistic colours from the Pantone palette and the photographic quality of digital printing.

Cutting & converting

Cutting and Converting

Both may be offered as elements of a larger project or individual services to the entrusted materials. Thanks to the variety of technologies available at our disposal, we are able to offer you both lead times and very competitive prices according to individual project requirements, whilst our flexible digital processes allow production of even single items.

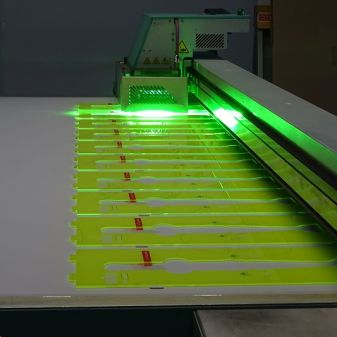

Digital

-

Kongsberg C64, working area 3200 x 3200 mm

-

Kongsberg X44, working area 2210 x 3200 mm

-

Kongsberg XN24, working area 1560 x 3050 mm

-

Kongsberg XN20, working area 1680 x 1270 mm

Flatbed plotters have many applications including cutting, perforating, creasing, milling, V-cutting. A great advantage is the large working fields and the ability to carry out 4 projects simultaneously on one device. With these 4 machines it gives great flexibility in the implementation time and very favorable prices!

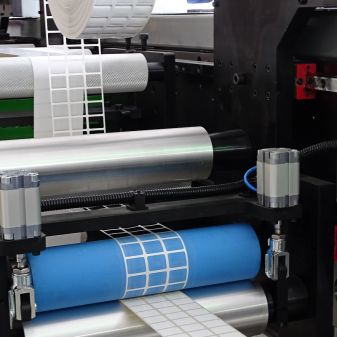

Rotating from role to role

The roller converting machine is responsible for such processes as: cutting, notching, creasing, lamination, delamination, die-cutting, relamination, rewinding, sheeting, numbering. It is intended for large-scale conversion of tapes, rubbers, felt, paper and foil.

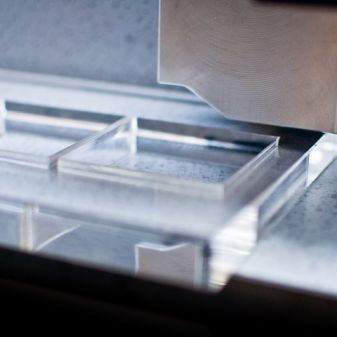

Milling

-

AXYZ 4008 milling machine, working field 1500 x 2400 mm.

The device has an automatic change system for 7 tools, a solid 3.5 kW spindle, dedicated to difficult surfaces such as Dibond, PMMA, PC, plywood, MDF, wood.

Guillotine, crucible.

In our machine park there are two guillotines and a crucible for shaping in a mechanical way. These are devices of a simple structure, with little mechanization, used for cutting blocks, sheets of paper, plastics, cardboard and other materials.

Kiss - cutting

Cutting process in which one layer is cut but the laminated backing paper is not. This technology is used for stickers, self-adhesive labels and similar applications. Kiss-cutting can be performed on a variety of materials such as self-adhesive films, papers, vinyls and more.

Converting self-adhesive materials

We specialize in shaping self-adhesive materials, rubbers, felt and other technical substrates. Thanks to our wide portfolio of cutting services, we adapt the technology to the material, achieving a competitive price!

Laser

We have several lasers. The maximum execution field is 1000 x 1500 mm. Power 1000 W. The devices have a high-precision linear motor. They are perfect for processing materials such as plywood or PMMA.

Perforation

It is a bookbinding activity consisting in cutting holes in paper, cardboard (or similar substrate) in a straight line to facilitate the detachment of its parts.

Processing

We offer a wide range of services and are able to work on a large variety of substrates. Although our work is mainly with plastics, cardboard, plywood, foils and tapes , we are also able to process aluminium, brass and similar materials. A wide portfolio of services allows us to implement multi-stage, comprehensive projects for the client. Our employees are fully versed in each of the latest technologies and we firmly believe that a trained operator ultimately ensures good quality of service and project success.

V-cutting

Technology used for processing cardboard, covers, honeycombs, rebord. It consists in making a V-shaped incision in the place of the crease.

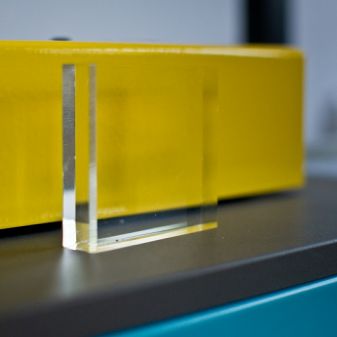

Flame polishing

Polishing is the process of producing a smooth and shiny edge of plastics. We make them with the diamond and flame techniques. Obtaining crystal edges makes the material look noble and extremely aesthetic.

Dimond polishing

Polishing is the process of producing a smooth and shiny edge of plastics. We make them with the diamond and flame techniques. Obtaining crystal edges makes the material look noble and extremely aesthetic.

Confectioning and packing

We offer a wide range of confectioning and packaging services. We approach each project individually, creating "made-to-measure" packaging, equipping the goods with labels, manuals and other elements necessary for good product logistics.

Fabric hemming

As part of textile processing we offer banner hemming, sewing keder (for stretched pictures on an aluminum frame) and velcro fastening.

UV varnishing

We perform UV varnishing with digital and screen printing technology. The main purpose of varnishing is to protect the print against mechanical damage and to improve the aesthetic value of the product. The varnish can be applied on the entire surface (apla) or fragmentarily.

Assembly and completion,

We provide assembly and completion services based on established procedures. Good logistics and assembly of components are important elements for the continuity of the project.

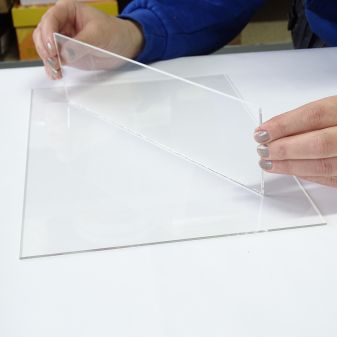

Lamination

Lamination consists in placing the foil on various substrates (including paper, cardboard, magnetic foil, etc.). The process is performed in hot and cold technology.

Gluing

We use various glueing techniques depending on the substrates and specific design requirements. We perform hot gluing, UV gluing, polymer gluing, and applying self-adhesive tapes. Our trained operators make every effort to ensure that gluing surfaces are made neatly and aesthetically.

Laminating

It is a kind of refinement of a paper product by wrapping it with thinner - printed or unprinted - paper.

Linear heat bending

We specialize in processing and linear bending of materials. We bend materials up to a length of 3000 mm and a thickness of 10 mm. We also process printed materials.

Chamfering

Anfasen ist das Schleifen der Kante eines Materials, um die Kanten zu glätten und ihm ein ästhetisches Aussehen zu verleihen.

Braille

The technology is based on installing steel or acrylic balls in a substrate with a thickness of at least 1.5 mm. The most commonly used materials for such projects are: Plastics (PVC, HIPS, PMMA, etc.), wood, HPL, MDF, HDF, Dibond.

Creasing

It is a bookbinding process whose purpose is to facilitate the folding of a specific material in an intended place.

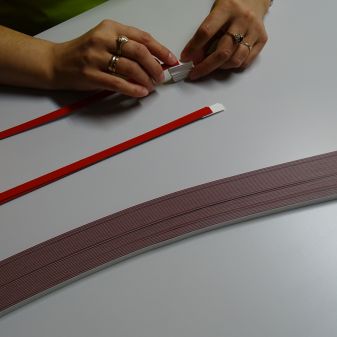

Adhesive tapes application

We make patterns from self-adhesive tapes and install them in accordance with the design assumptions, enabling product development and good service at a further production stage.

Do you need information?

Write to us!